3D-Printed Electronics Are the Future

Imagine printing a solar cell in a matter of minutes. Some business owners may think it sounds like something out of a science fiction story, but 3D printing is developing with ever-expanding capabilities including the possibility for 3D-printed electronics. The technology isn’t perfect yet, but researchers are hard at work developing ways for printers to create nanotech components from synthetics.

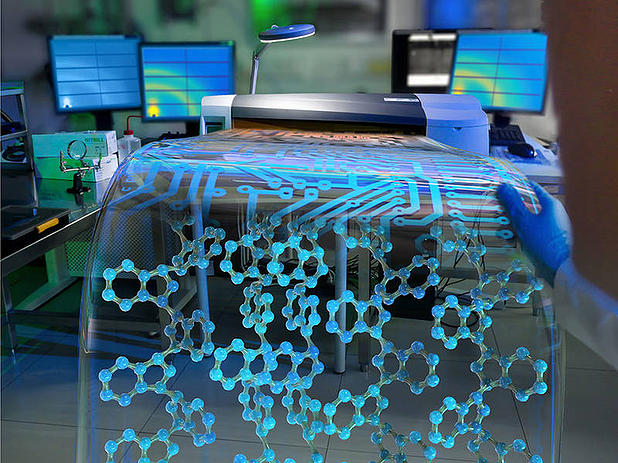

These so-called organic electronics rely on highly conductive materials that break the production mold. A team of researchers at Lawrence Berkeley National Laboratory in California and Technische Universität München (TUM) in Munich have been working to identify and improve upon the electrical properties of synthetic films. The TUM team recently reported that razor-thin polymer electrodes can be created on 3D printers using enhanced synthetic films.

Researchers in California can be thanked for these enhanced films. The team at Lawrence Berkeley used X-ray radiation to alter the molecular structure of freshly printed synthetic layers and worked in conjunction with the TUM researchers to determine how different post-printing processes affected the films. The international team plans to publish their results in Advanced Materials, an industry trade journal.

These new printing technologies are exciting, but more research is on the horizon. Making organic electronics is incredibly complex. The process will need to be closely observed and understood so that custom applications are possible in the future. Researchers are also working to perfect techniques to create the various layers in electronic components using only one process. This will increase convenience for manufacturers and will allow the large-scale use of 3D printing to create designer electronics.

There’s a great deal at stake here for businesses. Projected future markets for these technologies include solar cells, RFID tags, touch screens, glowing films and flexible displays. With future projects in development, such as wallpaper made of OLEDs, it is not surprising that organic electronics are expected to make a big impact on the consumer market thanks to this incredible range of applications.

Of course, the ability to print designer electronics on a 3D printer also significantly increases prototyping and bespoke design capabilities for small businesses. Instead of blowing their research and development budgets on electronics manufacturing, businesses will be able to print components in house for immediate testing. It may seem a distant dream now, but the enthusiasm of researchers in California and Munich indicates that printed electronics are closer than many might believe.