A Faster Way to 3D Print

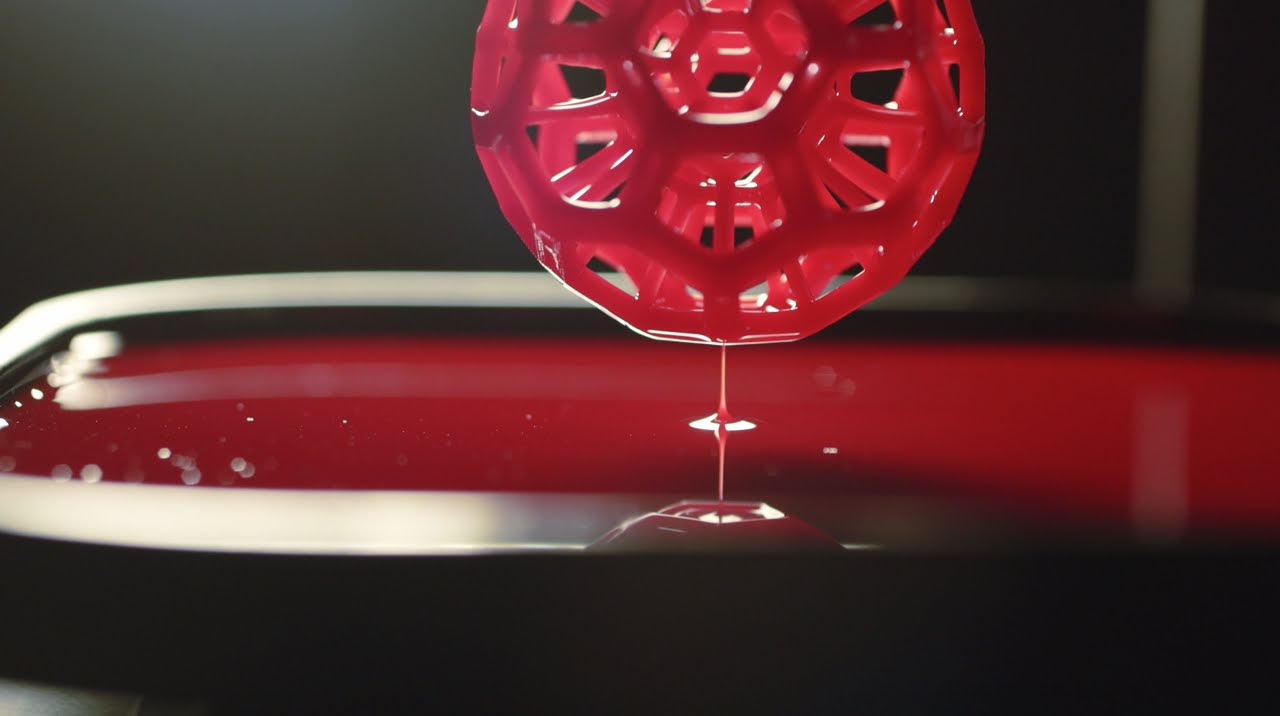

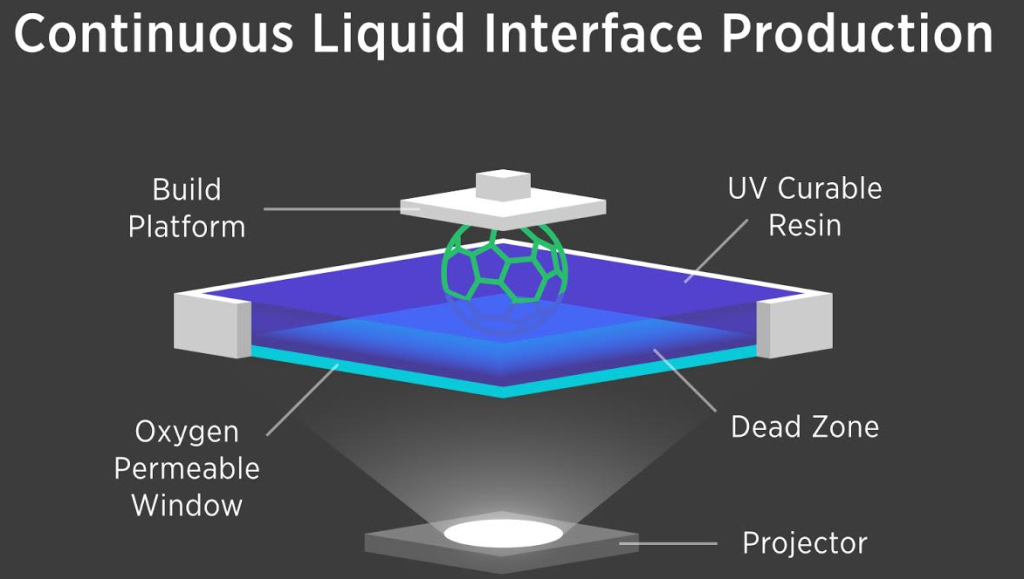

Carbon3D unveiled their Continuous Liquid Interface Production (CLIP) 3-D printer at the TED Conference in Vancouver last week. Their new technology allows CLIP to extrude objects from a pool of UV-sensitive material as opposed to using lasers on solids like conventional 3-D printers. Ultra-violet light is shined through an oxygen permeable membrane in the bottom of the pool to harden the resin. The process is 25-100 times faster than other printers.

Dr. Joseph DeSimone, CEO and co-founder of the company, demonstrated CLIP onstage by extruding a sphere of material in seven minutes, something that would have taken a standard 3-D printer ten hours to accomplish. This version of the printer is quite small and is able to create objects no larger than four inches wide and up to a foot tall. The demonstrations were all in polyurethane materials to form hard plastics. The company claims that it is also capable of printing rubber-like materials. Both of these materials are very useful in engineering and prototyping.

Dentistry may also have a use for CLIP. Competing companies are already marketing small 3-D printers for the industry and CNC milling machines to make crowns onsite in about 15 minutes. Using CLIP could cut that time by half. Another possibility is the movie and entertainment industry. They would be able to use the technology to create concept models and props in a fraction of the time currently required.

Carbon3D has not started selling CLIP yet, but they hope to have it on the market within a year. They are well funded for the next phase of their development. The small start up has raised over $41 million in capital so far from companies like Silver Lake Kraftwerk and Sequoia Capital.